Why Is Binchotan (Japanese White Charcoal) Special?

Have you ever dined at a Japanese charcoal grill restaurant? Do you know how tasty the food is? One of the secrets is binchotan.

- Authentic binchotan charcoal has excellent thermal power and a long burn time, and it is widely used in Japanese restaurants that use charcoal fires.

- Binchotan should last for around 3 to 5 hours without needing to be replaced.

- The charcoal can be extinguished and reused if it has not burned out.

- Binchotan takes longer to light because of its density.

- Binchotan is the most expensive charcoal in the world.

You can immediately tell the difference in quality after using the charcoal just once. When you hold a piece of premium binchotan, you can feel its weight and density. Premium varieties come in a long and round shape. The shiny interior can be seen when a piece is broken.

How to Find Quality Binchotan?

Binchotan is available in a variety of types and at a range of prices. Authentic binchotan is extremely expensive, but you cannot go back to the cheap stuff after trying the real thing.

Before joining My Cookware®, I had the opportunity to visit Wakayama and learn about the production process of binchotan. In this article, I explain how binchotan is made so that one can appreciate its value.

Keep to the Place of Origin

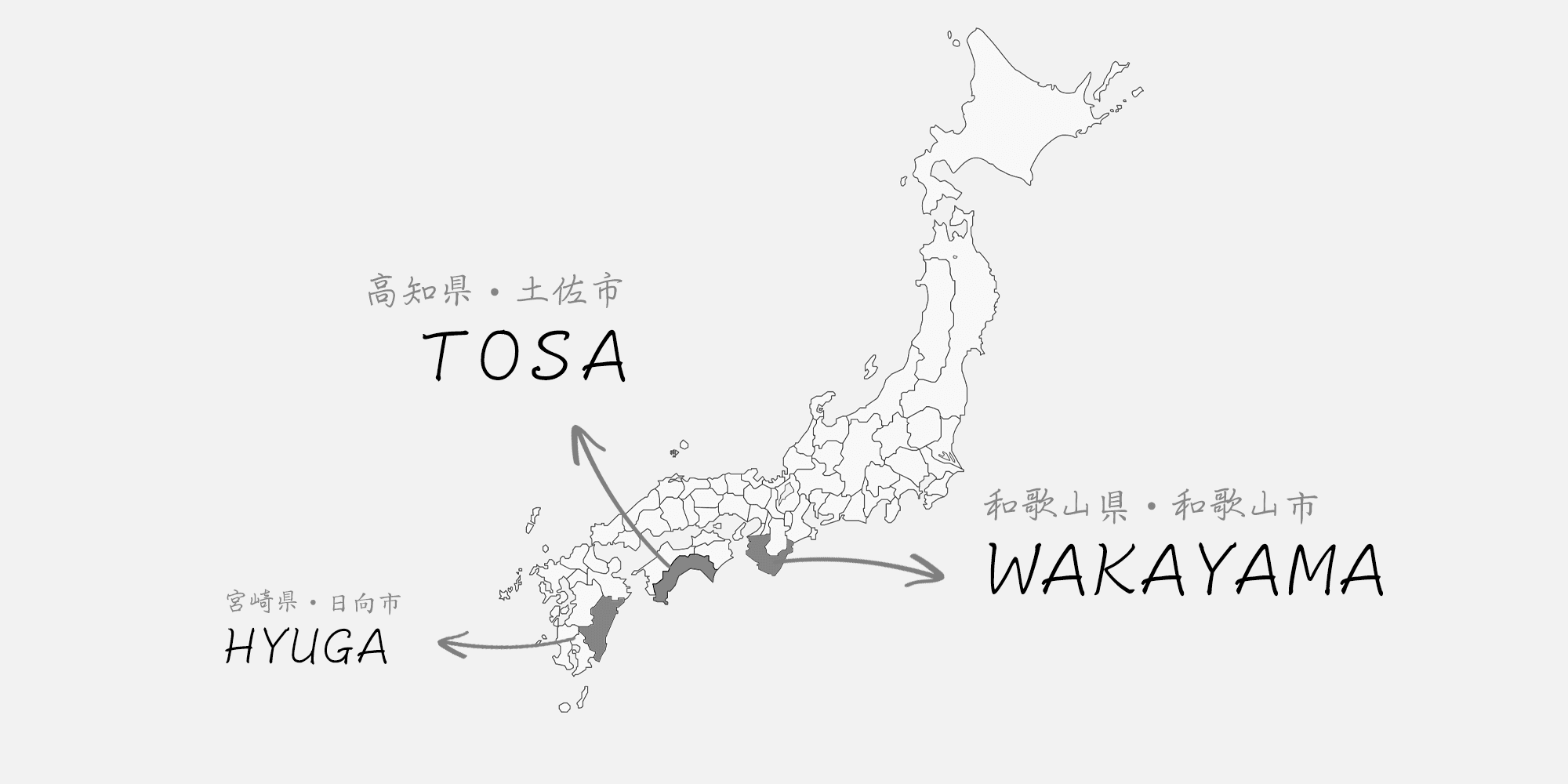

If you are not sure what binchotan to buy, focus on its origin. Traditionalists generally recommended three major production areas: Kishu binchotan (Wakayama), Tosa binchotan (Kochi) and Hyuga binchotan (Miyazaki). On our website, you will find binchotan from Kishu and Tosa. Supplies are very limited, so these sites are occasionally out of stock.

Kishu is an old name for Wakayama. Because the name is so traditional, people continue to refer to Wakayama binchotan as "Kishu binchotan." White charcoal made in modern-day Wakayama, the birthplace of binchotan, is considered the best. Tosa and Hyuga are also excellent, though. When struck, top quality binchotan from any of these production sites makes a metallic sound.

What Is the Process of Making Top-Quality Binchotan?

If you go and speak to some of the young men working in one of these binchotan production sites, you will learn that they are doing the same job their great-grandfathers did. They are charcoal-burning craftsmen.

Binchotan's quality depends on the quality of the raw wood and the traditional processing technique. Here is how it works:

Week 1

The quality of the oak determines the quality of the charcoal. These raw oak pieces are placed in a kiln during week one. Smoke is used to extract as much water as possible from the tree. This process requires a great deal of patience.

Obviously, if the craftsmen smoke the wood nonstop, the process will be completed earlier, but the quality will be inferior. Hence, it is necessary to cycle the heat from time to time.

Experienced craftsmen determine whether the oak is in danger of overheating or when it is time to stop. During the first week, it is important to ensure that the oak is completely dry. The final product will be significantly degraded if there is any residual water in the oak.

There were many brands that tried to imitate the Japanese way of making binchotan, but because they aimed for mass production, they needed to shorten the process. This is what makes achieving the quality of Kinsu and Tosa binchotan difficult.

Week 2

The second week is crucial and requires further craftsmanship. Upon reaching a certain temperature in the kiln, the oak is lit on fire. The fire burns for one week -- yes, one whole week.

In order to keep the temperature at a proper level, the craftsmen need to adjust the amount of air entering the kiln. In order to ensure that binchotan burns evenly, it is necessary to control the amount of oxygen going into it.

Once the oak becomes red, it is already binchotan. Craftsmen then remove the binchotan immediately and extinguish it with white ash. This is the birth of a perfect piece of binchotan.

Binchotan (Japanese white charcoal) Represents the Excellence of Japanese Craftsmanship

Binchotan is charcoal covered in white ash. That is why it is also called Japanese white charcoal. Binchotan weighs more than regular black charcoal because of its higher density. Here is a rough representation of how authentic binchotan is made.

Binchotan is charcoal covered in white ash. That is why it is also called Japanese white charcoal. Binchotan weighs more than regular black charcoal because of its higher density. Here is a rough representation of how authentic binchotan is made.

Craftsmen produce a batch of binchotan in two weeks. There are only two batches per month. This explains why the product is always in short supply overseas. The traditional method cannot be replaced.

To make binchotan, the kiln needs to have a very high level of insulation to prevent air from entering and to maintain heat inside. Charcoal quality is determined by the kiln quality as well as the technique used by the charcoal makers.

Binchotan charcoal is an example of Japanese craftsmanship at its best.

Click here for all binchotan products.

- The article was written by Kai, a product specialist at My Cookware®.

COPYRIGHT WARNING: Content theft of any kind is immediately reported to Google, which results in ranking penalties. Original texts can be verified in internet archives. My Cookware Australia® holds the copyrights for all the content on this site, including articles, product descriptions, and user guides.